Tool Owner

Jim Pierce (jim.pierce@utah.edu)

Reservations Calendar

- Automated sputter deposition of metals, alloys, and insulating thin films

- Four confocal cathodes, inclined 25 degrees off vertical

- Std targets 4″ Au, 4″ Cr, 3″ Pt, 3″ Ti

- Other targets by arrangement with staff

- Film thicknesses controllable from a few nm to hundreds of nm

- Sputter power supplies, DC1 pulse or DC, DC2, RF1

- Switch-control any supply to any cathode

- Co sputter capable

- Substrate sputter pre-clean with RF2 supply

- PEM controllable reactive sputtering (Nitrogen or Oxygen)

- 8″ Diameter stage

- Substrate rotation

- +/- 5% Uniformity

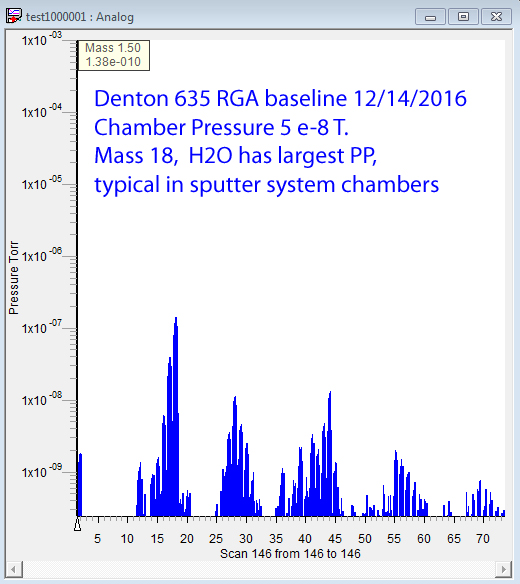

- Cryo pumped to 5 x 10^-8 Torr

- Substrate heat up to 500 C (heated stage installed)

- Liftoff deposition with water-cooled stage (std configuration)

- Argon pressure range < 1-90 mT controllable with APC and 100 sccm MFC controller

Equipment Monitor

S/N: 69469

SOP:

Run-Data Reports for Denton 635

| Processes on Denton 635 |

|---|